Aluminium Cold Dross Processing Plant

2000000 INR/Piece

Product Details:

- Product Type Aluminium Cold Dross Processing Plant

- Material Mild Steel / Stainless Steel

- Capacity 5 Ton/day

- Application Processing and recovering aluminium from cold dross

- Weight Approx. 2000-3500 kg

- Dimension (L*W*H) 4200 mm x 1850 mm x 2200 mm

- Color Blue & Silver (customizable)

- Click to view more

X

Aluminium Cold Dross Processing Plant Price And Quantity

- 2000000 INR/Piece

- 1 Piece

- Water or Air Cooled options

- Ambient / No need of external heating

- 40-60 kW

- Low

- Semi-Automatic or Automatic

- Up to 500 mm

- Up to 90% recovery rate

- PLC Based

- Available

- 3 Phase

Aluminium Cold Dross Processing Plant Product Specifications

- Approx. 2000-3500 kg

- 5 Ton/day

- Mild Steel / Stainless Steel

- Aluminium Cold Dross Processing Plant

- Blue & Silver (customizable)

- 4200 mm x 1850 mm x 2200 mm

- Processing and recovering aluminium from cold dross

- Water or Air Cooled options

- Ambient / No need of external heating

- 40-60 kW

- Low

- Semi-Automatic or Automatic

- Up to 500 mm

- Up to 90% recovery rate

- PLC Based

- Available

- 3 Phase

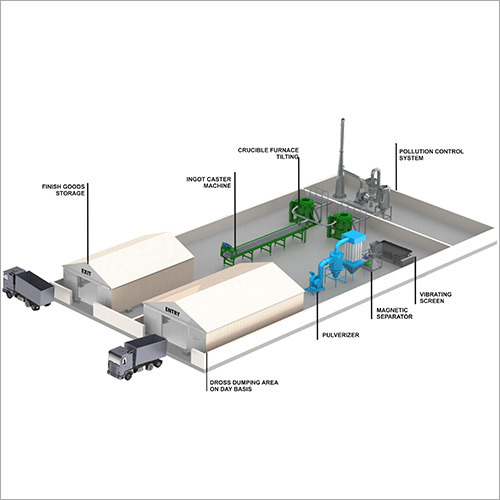

Product Description

Aluminium Cold Dross Processing Plant is utilized to separate feeds from crushed ores and is widely employed in coal mines. Our skilled engineers at our production facility use the cutting-edge methodology to create the offered machine using premium-grade parts. Before being sold on the market, the products that we produce are machine-tested. Aluminium Cold Dross Processing Plant is further tested against many quality indicators in accordance with established industry standards and rules. This plant requires very low maintenance and replacement costs.

Efficient Aluminium Recovery

Maximize your aluminium yield with our advanced dross processing plant, achieving up to 90% recovery without the need for energy-intensive external heating. The fully or semi-automatic system, adjustable for diverse operational needs, handles feed sizes up to 500 mm, ensuring flexible processing for various industrial applications.

Flexible Operation and User-Friendly Control

Equipped with a reliable PLC-based control system, the plant offers seamless operation whether you choose the automatic or semi-automatic option. Its user interface is designed for straightforward operation and monitoring, allowing operators to optimize the process efficiently and safely.

Durable Construction and Customization Options

Built from mild steel or stainless steel, the plant guarantees long-lasting service in demanding environments. Customizable in blue and silver, it fits into different industrial aesthetics. Compact dimensions and a robust frame make installation and integration straightforward for manufacturers and recyclers alike.

FAQ's of Aluminium Cold Dross Processing Plant:

Q: How does the aluminium cold dross processing plant operate without external heating?

A: The plant is specifically engineered to process aluminium dross at ambient temperatures, utilizing its unique mechanical separation system. This eliminates the need for any energy-intensive external heating, ensuring efficient metal recovery while reducing operational costs.Q: What benefits does the PLC-based control system provide for operators?

A: The PLC (Programmable Logic Controller) based control system streamlines the plant's operation, reduces manual intervention, and allows for consistent and precise process management. It enhances reliability, safety, and can be adapted for both semi-automatic and automatic functioning as per user requirements.Q: When is it recommended to choose water-cooled over air-cooled options in this plant?

A: The choice between water and air cooling depends on operational requirements and environmental conditions. Water-cooled systems are generally preferred in hotter climates or where rapid heat dissipation is needed, while air-cooled options suit moderate environments with effective ventilation.Q: What types of facilities can install this processing plant in India?

A: This plant is ideal for foundries, aluminium recycling businesses, and secondary aluminium manufacturers seeking to recover metal from cold dross. Its customizable design and after-sales support make it suitable for dealers, exporters, manufacturers, suppliers, and wholesalers across India.Q: How does the processing plant achieve up to a 90% aluminium recovery rate?

A: Thanks to its advanced separation mechanism and optimized material flow, the plant ensures maximum extraction of aluminium from dross. The efficient design minimizes loss and enhances overall recovery rates, leading to sustainable and profitable operations.Q: What after-sales services are available for this aluminium dross processing plant?

A: Comprehensive after-sales services are provided, including installation assistance, staff training, technical support, and fast spare parts supply. This ensures minimal downtime and a smooth operational experience for all users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Metal Recycling Plant' category

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free