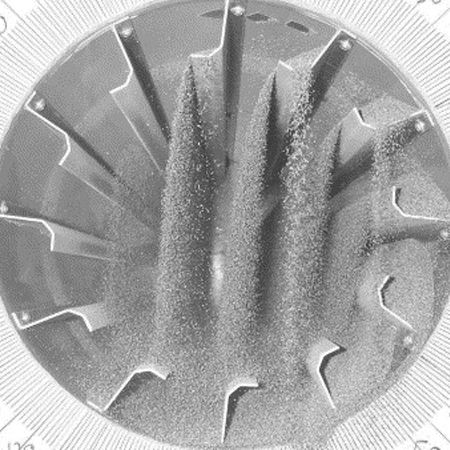

Industrial Rotary Dryer

1000000 INR/Unit

Product Details:

- Material Metal

- Computerized No

- Automatic Grade Semi-Automatic

- Control System Human Machine Interface

- Color Orange, Black

- Warranty Yes

- Click to view more

X

Industrial Rotary Dryer Price And Quantity

- 1 Unit

- 1000000 INR/Unit

- 1000000.00 - 2000000.00 INR/Unit

Industrial Rotary Dryer Product Specifications

- Orange, Black

- Human Machine Interface

- Semi-Automatic

- Yes

- Metal

- No

Industrial Rotary Dryer Trade Information

- JNPT Port

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Cheque

- 10 Unit Per Month

- 4 Week

- North America, South America, Eastern Europe, Middle East, Western Europe, Africa, Central America, Asia, Australia

- All India

Product Description

With rich industry experience, we are occupied in offering an extensive assortment of industrial Rotary Dryer. The given product is used in different industries like cement, metallurgy and chemical. With better adaptability and perfect workmanship, this dryer is very popular among our clients. This dryer is designed and made utilizing the finest quality components under the supervision of experienced engineers in strict adherence with the set industrial standard. Our product is delivered to the customers in a designated time frame owing to our expert delivery team.

Rotary Dryer FAQ:

Q. How does a rotary dryer work?

Ans: The material to be dried is fed into the rotating drum or cylinder. As the drum rotates, the material is lifted by flights (internal lifting fins) and cascades through the heated gas stream. This direct contact with the hot gas facilitates the transfer of moisture from the material to the gas, thereby drying the material.

Q. What types of fuels can be used to heat a rotary dryer?

Ans: Rotary dryers can be heated using various fuels such as natural gas, propane, diesel, coal, biomass, or electricity, depending on availability, cost, and environmental considerations.

Q. What factors determine the size and capacity of a rotary dryer?

Ans: The size and capacity of a rotary dryer depend on factors such as the moisture content of the feed material, the desired moisture content of the final product, the materials characteristics (e.g., particle size, density), the drying temperature, and the residence time required for effective drying.

Q. What are the advantages of using a rotary dryer?

Ans: Some advantages of rotary dryers include their ability to handle a wide range of materials and moisture levels, their high throughput capacity, relatively low operating costs, and their ability to produce uniformly dried products with minimal dust emissions.

Q. What are the limitations of rotary dryers?

Ans: Limitations of rotary dryers include their high initial capital cost, the need for continuous monitoring and maintenance, potential for material degradation or overheating if not operated properly, and limitations on the maximum moisture reduction achievable for certain materials.

Q. Can rotary dryers be customized for specific applications?

Ans: Yes, rotary dryers can be customized with features such as different drum sizes and configurations, varying flight designs, specialized heating systems, and controls to meet the specific requirements of different materials and applications.

Q. How do I optimize the performance of a rotary dryer?

Ans: To optimize the performance of a rotary dryer, factors such as feed rate, inlet and outlet temperatures, drum speed, air flow rate, and residence time should be carefully monitored and adjusted as needed. Regular maintenance, including cleaning and inspection of components, is also essential for optimal performance and longevity.

Q. Are there safety considerations when operating a rotary dryer?

Ans: Yes, safety considerations include proper ventilation to prevent the buildup of combustible gases, ensuring adequate insulation and guarding to prevent contact with hot surfaces, implementing emergency shut-off systems, and providing appropriate training for operators to handle the equipment safely.

FAQs of Industrial Rotary Dryer:

Q: What is the automatic grade of the Industrial Rotary Dryer?

A: The automatic grade of the Industrial Rotary Dryer is Semi-Automatic.Q: What color options are available for the Industrial Rotary Dryer?

A: The Industrial Rotary Dryer is available in Orange and Black colors.Q: Is the control system computerized for the Industrial Rotary Dryer?

A: No, the control system for the Industrial Rotary Dryer is Human Machine Interface.Q: What is the material of the Industrial Rotary Dryer?

A: The Industrial Rotary Dryer is made of metal.Q: Does the Industrial Rotary Dryer come with a warranty?

A: Yes, the Industrial Rotary Dryer comes with a warranty.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free