Zinc Recycling Plant

Product Details:

- Product Type Zinc Recycling Plant

- Material Heavy Duty Mild Steel and Stainless Steel Construction

- Capacity 3 to 40 Tons per Day (depending on design and requirements)

- Application Used for recycling and recovering Zinc from scrap materials, suitable for use in metal recovery plants and smelting industries

- Weight Approx. 20-30 Tons (varies with plant configuration)

- Dimension (L*W*H) Approx. 18000 mm x 7000 mm x 9000 mm

- Color Industrial Blue-Grey (customizable)

- Click to view more

X

Zinc Recycling Plant Product Specifications

- Industrial Blue-Grey (customizable)

- 3 to 40 Tons per Day (depending on design and requirements)

- Approx. 18000 mm x 7000 mm x 9000 mm

- Heavy Duty Mild Steel and Stainless Steel Construction

- Zinc Recycling Plant

- Used for recycling and recovering Zinc from scrap materials, suitable for use in metal recovery plants and smelting industries

- Approx. 20-30 Tons (varies with plant configuration)

Product Description

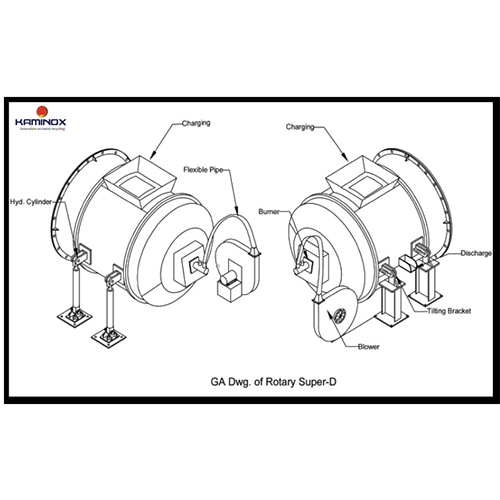

The ability to tilt and rotate the zinc recycling plant is its main advantage. Prior to locking the furnace, lead scrap is placed inside with smelting flux. The material is heated until it reaches the melting point using an oil/gas burner that is installed on the door. Less energy is required to make metal, making it more economical. Fewer quarries and mines, less noise, and lighter traffic all contribute to a lower environmental impact. conserves precious raw materials; metal ore reserves will last longer.

Zinc Recycling Plant FAQ:

Q. What is a zinc recycling plant?

Ans: A zinc recycling plant is a facility where zinc-containing materials, such as zinc scrap, galvanized steel scrap, and zinc residues from various industrial processes, are processed to recover zinc metal for reuse.

Q. How does a zinc recycling plant work?

Ans: In a zinc recycling plant, zinc-containing materials are typically shredded, sorted, and processed in a furnace or smelter. The materials are heated to high temperatures, causing the zinc to melt and separate from other metals and impurities. The molten zinc is then purified and cast into ingots or other forms for reuse in various industries.

Q. What types of materials are processed in a zinc recycling plant?

Ans: Zinc recycling plants typically process a variety of zinc-containing materials, including zinc scrap from industrial processes, galvanized steel scrap from demolished buildings or vehicles, zinc residues from zinc refining or plating operations, and zinc-containing electronic waste (e-waste).

Customizable Automation for Diverse Needs

Choose between semi-automatic and fully automatic operation to match your operational requirements and budget. Our zinc recycling plants are designed to scale from 3 to 40 tons per day. This adaptability makes them ideal for both small and large recycling facilities, providing enhanced control through digital PLC-based panels.

Efficient Pollution Control and Safety Standards

Every plant is fitted with advanced emission control systems to meet environmental standards. Operating at temperatures up to 1200C, the unit's pollution control equipment effectively manages and minimizes hazardous emissions, ensuring a safer workplace and compliance with regulatory norms.

Advanced Metal Recovery Technology

Through a combination of pyrometallurgical and hydrometallurgical processes, our systems achieve up to 96% zinc extraction efficiency. This high recovery rate helps maximize your return on investment and minimizes waste, making the plant well-suited for metal recovery and smelting industries.

FAQ's of Zinc Recycling Plant:

Q: How does the zinc recycling plant achieve up to 96% zinc recovery efficiency?

A: The plant employs advanced pyrometallurgical and/or hydrometallurgical processes in combination with precisely controlled rotary or tilting furnaces, enabling optimal extraction of zinc from feed materials such as ash, dross, skimmings, and scrap.Q: What feed materials can be processed in this zinc recycling plant?

A: This plant can handle a range of zinc-containing materials, including zinc ash, zinc dross, zinc skimmings, and other scrap, making it suitable for diverse metal recovery applications.Q: When is it necessary to opt for a fully automatic setup over a semi-automatic one?

A: A fully automatic plant is ideal for larger operations requiring minimal manual intervention, higher throughput, and advanced monitoring, while a semi-automatic configuration suits plants with moderate production volumes and more hands-on management.Q: Where can this zinc recycling plant be installed?

A: Designed for flexibility, the plant can be installed in industrial zones, metal recovery facilities, or smelting industries, with onsite installation, training, and support provided by our team anywhere in India.Q: What is the process used for zinc recovery in this plant?

A: Depending on configuration, the plant uses pyrometallurgical (high-temperature treatment) and/or hydrometallurgical (chemical leaching) methods to recover zinc efficiently from various scrap materials.Q: How does the system control emissions during operation?

A: The plant integrates pollution control equipment that effectively captures and treats emissions generated during the recycling process, ensuring compliance with environmental standards and workplace safety.Q: What are the benefits of using this zinc recycling plant for your facility?

A: Users benefit from high zinc recovery rates, customizable automation, robust construction, low emissions, and dedicated service support, resulting in increased productivity, reduced losses, and improved environmental compliance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Metal Recycling Plant' category

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free